Remember that time you were helping build a patio in your backyard? You tirelessly mixed concrete, but something felt off. The consistency seemed wrong, and the final product felt too light. What you unknowingly encountered was the impact of varying concrete densities. While it might seem like a straightforward material, understanding the density of concrete is crucial for achieving the desired strength and durability in any construction project.

Image: 9to5civil.com

Density, simply put, is the measure of how much mass is packed into a given volume. In this case, we’re looking at the mass of concrete per cubic meter (kg/m3). This seemingly simple calculation plays a massive role in the overall performance and suitability of concrete for different applications. Let’s take a closer look at what makes concrete’s density such a critical factor.

What Influences the Density of Concrete?

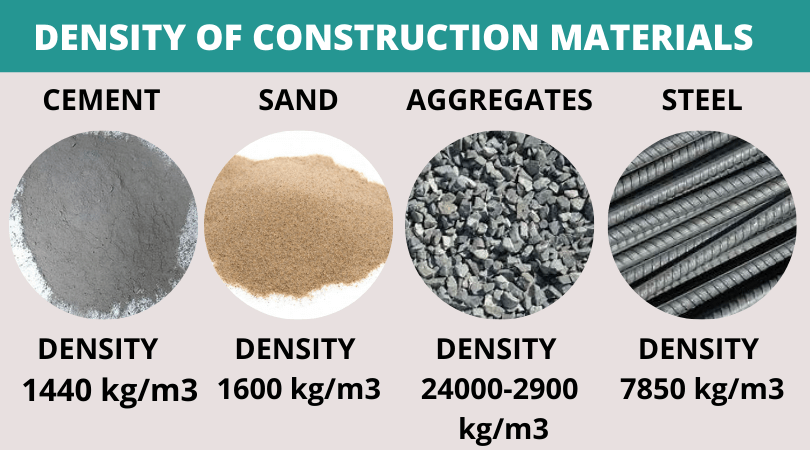

The density of concrete is not a fixed value but rather a dynamic factor influenced by various components. The key elements that dictate the density include:

1. Water-Cement Ratio:

The water-cement ratio, a fundamental principle in concrete mixing, significantly impacts the density. A higher water-cement ratio leads to a more fluid mix, but it also results in weaker concrete with lower density. Conversely, a lower water-cement ratio creates a denser, stronger concrete mix.

2. Aggregate Type and Size:

Aggregates, the small rocks and sand that make up the majority of concrete, contribute heavily to its density. The type of aggregate (gravel, crushed stone, etc.) and their size influence the overall mass packed into a given volume. Larger aggregates generally lead to a higher density.

Image: civilsir.com

3. Cement Type:

Different types of cement, such as portland cement or blended cements, possess distinct properties. Some cements result in denser mixes compared to others. For instance, high-strength cements, due to their greater particle size, might produce a higher concrete density.

4. Air Content:

Air entrained in the concrete mix affects the density. Air bubbles, while adding workability and frost resistance, decrease the overall density of the concrete.

Common Density Ranges of Concrete:

The density of concrete commonly falls within a range of 2,200 to 2,500 kg/m3, though it can fluctuate depending on the factors outlined above. Here’s a breakdown of typical density ranges for different concrete types:

- Normal-weight concrete: 2,300-2,500 kg/m3

- Lightweight concrete: 1,400-2,000 kg/m3. This type often uses lightweight aggregates like expanded clay or shale.

- Heavy-weight concrete: 2,500-3,000 kg/m3. This variety incorporates heavy aggregates like iron ore or steel shot.

Why Density Matters:

Concrete density isn’t just a technical detail. Here’s why it profoundly impacts your project:

1. Strength and Durability:

A higher density in concrete generally corresponds to increased strength and durability. The closely packed particles offer greater resistance to stress and strain. This is particularly vital in structures subjected to heavy loads.

2. Structural Load-Bearing Capacity:

The density of concrete directly impacts its load-bearing capacity. A denser concrete mix can support heavier structures and loads, making it ideal for high-rise buildings, bridges, and other demanding construction projects.

3. Thermal Properties:

Density influences the thermal properties of concrete. Higher density generally results in better heat insulation and thermal conductivity. It’s an important factor in considering the energy efficiency of buildings during design and construction.

4. Cost:

The density of concrete can impact its associated costs. Higher density often means using more materials, which can increase production costs. However, remember that using denser concrete might also allow for a thinner slab or wall, potentially reducing material use in the long run.

Modern Trends in Concrete Density:

The construction industry is constantly evolving, and the quest for optimal concrete density is no exception. Current trends include:

- Sustainable Concrete: The focus on sustainable building practices has led to innovative concrete mixtures that utilize recycled materials and minimize the environmental footprint. Sustainable concrete often aims to achieve a specific density range for optimal performance and resource efficiency.

- Self-Consolidating Concrete: This type of concrete, known for its exceptional flowability and ability to self-compact, offers advantages in construction efficiency and reduces labor costs. Self-consolidating concrete blends tend toward a specific density range to ensure proper hydration and consolidation.

- High-Performance Concrete: High-performance concrete (HPC) boasts enhanced strength, durability, and workability, often tailored to meet specific project demands. As a result, the density of HPC formulations requires careful control and might deviate from traditional concrete mixes.

Tips for Optimizing Concrete Density:

Here are some practical tips based on my experience as a blogger and researcher to ensure you’re using concrete with the right density:

- Choose the Right Aggregate: Select aggregates that meet the required density for the specific application. Larger aggregates generally contribute to higher density.

- Minimize Water-Cement Ratio: Opt for a lower water-cement ratio for a denser mix, leading to greater strength and durability.

- Utilize Proper Mixing Techniques: Ensure thorough mixing of concrete ingredients to achieve a homogeneous mix and consistent density.

- Proper Curing: Allow concrete to cure properly, which involves maintaining adequate moisture and temperature, to achieve the desired density and strengthen the material.

- Consult an Expert: Don’t hesitate to seek guidance from qualified professionals, such as engineers or concrete specialists, to ensure the right concrete mix design for your project needs.

These tips can help you achieve the correct density for your specific construction project and ensure optimal performance and durability. However, remember that proper design, mixing, and curing practices are essential for achieving a dense and robust concrete structure. Always ensure you’re following the guidelines and recommendations from your local building codes and construction companies.

Frequently Asked Questions (FAQ)

Here are some commonly asked questions about the density of concrete:

Q: How do I calculate the density of concrete?

A: You can calculate the density of concrete by dividing the mass of the concrete by its volume. The density is typically expressed in kilograms per cubic meter (kg/m3).

Q: What is the ideal density for concrete?

A: There is no single “ideal” density. The ideal density depends on the specific application and design requirements. Structural engineers and project specifications will guide the appropriate density.

Q: Does the density of concrete affect its compressive strength?

A: Yes, generally, a higher density in concrete results in greater compressive strength. Denser concrete offers greater resistance to crushing forces.

Q: Can I easily change the density of concrete once it is poured?

A: No, once the concrete is poured, it is difficult to alter its density. This is why careful planning and accurate mixing are crucial for achieving the desired density.

Density Of Concrete In Kg M3

Final Thoughts

Understanding the density of concrete is a crucial aspect of successful construction projects. Whether you’re involved in building a small home addition or a large-scale infrastructure project, always keep the density factor in mind. By carefully selecting materials, adhering to proper mixing practices, and ensuring adequate curing, you can achieve a robust and long-lasting concrete structure. Do you have any further questions or want to explore specific density calculations for your project? We’d love to hear your thoughts!