Have you ever wondered how a massive engine like the Paccar MX-13, powering heavy-duty trucks across vast distances, manages to sip fuel with remarkable efficiency? The answer lies within the intricate workings of its fuel system. This complex and fascinating network, composed of pumps, filters, injectors, and sensors, ensures a consistent and precise delivery of fuel, maximizing performance while minimizing waste. In this comprehensive guide, we’ll delve into the depths of the Paccar MX-13 fuel system, unraveling its components, functions, and importance in the world of trucking.

Image: www.cmvtruckcentre.com.au

Understanding the Paccar MX-13 fuel system is crucial for anyone involved in the trucking industry, from mechanics and operators to fleet managers and enthusiasts. A well-maintained fuel system translates into optimal performance, fuel economy, and reduced emissions. It also helps identify and troubleshoot any potential issues, preventing costly downtime and ensuring the smooth operation of these powerful workhorses on the road.

The Heart of the System: Components Explained

Fuel Tank, Filtration, and Delivery

The journey of fuel begins in the fuel tank, where it’s stored and protected from external elements. The fuel then enters the fuel filter, a crucial component that removes impurities and contaminants that could clog the delicate fuel injectors. This ensures clean fuel reaches the engine, vital for preventing damage and ensuring smooth operation.

The fuel pump, often an electric-powered unit, plays a critical role in pressurizing the fuel and sending it to the engine. This pressurized fuel is then directed to the common rail, a high-pressure fuel rail that distributes fuel evenly to the injectors. The common rail system ensures precise and consistent fuel delivery to each cylinder, optimizing combustion and performance.

The Brains of the Operation: Sensors and Controls

The Paccar MX-13 fuel system isn’t just about moving fuel; it’s about controlling it with precision. Fuel pressure sensors monitor the pressure in the common rail, while temperature sensors measure fuel temperature. This data is transmitted to the engine control module (ECM), the brain of the system, which interprets the information and makes adjustments to ensure optimal fuel delivery.

The ECM also receives signals from other sensors, such as the throttle position sensor and speed sensor, to determine the engine’s operating conditions and adjust the fuel delivery accordingly. This sophisticated control system allows the engine to respond instantaneously to changes in load and driving conditions, optimizing performance and fuel efficiency.

Image: styleanddelinquency.blogspot.com

The Final Stage: Injectors and Combustion

The fuel injectors, strategically located at the top of each cylinder, are the final stage in the fuel delivery process. These precisely controlled valves open and close, delivering a precise amount of fuel into the combustion chamber at the optimal time. The precisely timed injection of fuel leads to efficient combustion, maximizing power and reducing emissions.

The combustion process itself is fascinating. The fuel, ignited by the spark plug, burns rapidly, producing pressure that pushes the piston down and turns the crankshaft. This energy, harnessed through a complex mechanical system, ultimately powers the wheels of the truck, propelling it forward. The entire fuel system works harmoniously to ensure this process happens seamlessly and efficiently.

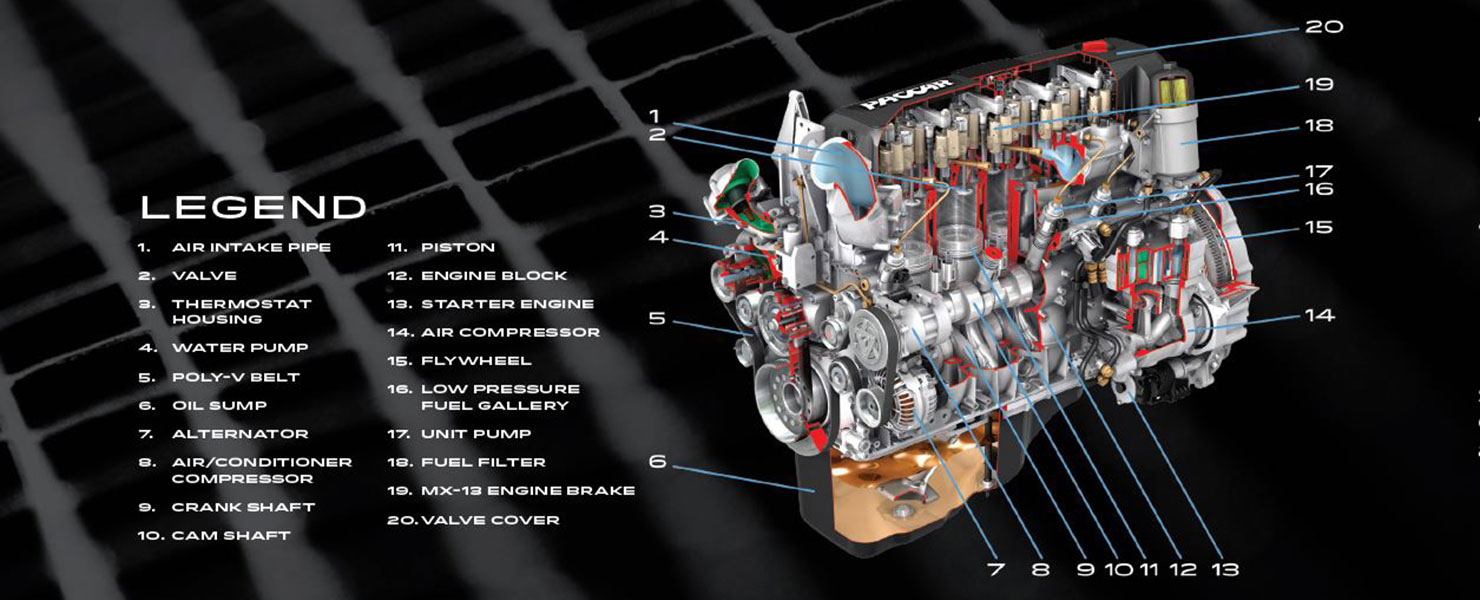

Understanding the Diagram: A Visual Guide

A comprehensive fuel system diagram is invaluable for understanding the flow of fuel and the interaction of different components. The diagram typically features different components represented by symbols, linked by lines representing the flow of fuel. It can also highlight the control paths, showing how the ECM receives data from sensors and adjusts fuel delivery.

By examining the diagram, one can gain insights into the complexity of the system, identifying key components and their functions. It serves as a visual map, making it easier to comprehend the interconnectedness of fuel delivery, control, and combustion in a modern diesel engine. To find a comprehensive diagram of the Paccar MX-13 fuel system, you can consult online resources, service manuals, or specialized automotive websites.

Maintaining the Fuel System: Ensuring Long Life and Efficiency

As with any complex system, regular maintenance is crucial for the Paccar MX-13 fuel system. This includes scheduled fuel filter replacements, ensuring the removal of contaminants and preventing clogging. Regular inspections are also vital, including visual checks for leaks, worn components, or damage. Any problems should be addressed immediately to prevent further damage or engine issues.

It’s important to use high-quality fuel, as impurities can harm the fuel injectors and lead to premature wear. Using fuel additives specifically designed for diesel engines can also help protect the fuel system and improve combustion. Adhering to these maintenance practices ensures the longevity of the fuel system, maximizing performance and minimizing fuel consumption.

Fuel System Advancements: Driving Efficiency and Sustainability

The Paccar MX-13 fuel system is constantly evolving, driven by innovations in technology and the quest for increased efficiency and sustainability. Modern advancements include:

- Advanced Fuel Injection Systems: These systems employ sophisticated electronic controls and higher injection pressures for even more precise fuel delivery, optimizing combustion and reducing emissions.

- Variable Geometry Turbochargers (VGT): By adjusting the turbine blades, VGTs optimize engine power and responsiveness across a broader range of engine speeds, leading to improved fuel efficiency.

- Exhaust Gas Recirculation (EGR): EGR systems are a vital part of reducing NOx emissions. They recirculate exhaust gases back into the combustion chamber, lowering combustion temperatures and reducing NOx formation.

- Diesel Particulate Filters (DPF): DPFs trap soot particles from the exhaust, preventing their release into the environment. They are a key component in meeting increasingly stringent emission standards.

These advancements not only contribute to fuel economy but also play a critical role in reducing environmental impact. As technology continues to evolve, we can expect even more refined and efficient fuel systems in the future, further enhancing the performance and sustainability of heavy-duty trucks equipped with the Paccar MX-13 engine.

Paccar Mx 13 Fuel System Diagram

Conclusion: The Power of Precision

The Paccar MX-13 fuel system is a marvel of engineering, showcasing how meticulous control and precision can optimize performance in a powerful engine. From the fuel tank to the injectors, each component plays a vital role in ensuring efficient fuel delivery, optimized combustion, and maximized performance. Understanding this system is crucial for anyone working with the Paccar MX-13 engine, allowing for proper maintenance, troubleshooting, and appreciation of the intricate mechanisms that keep these trucks moving across the road.

We encourage you to continue exploring this fascinating topic. Consult online resources, service manuals, and technical forums to further your knowledge and gain a deeper understanding of the Paccar MX-13 fuel system. You can also consider joining online communities of truck enthusiasts and mechanics for sharing information and exchanging experiences. By understanding the intricacies of this system, we can better appreciate the engineering prowess that powers the heavy-duty trucking industry and the vital role fuel systems play in driving performance, efficiency, and sustainability.